Our latest teardown reveals Apple’s design tricks

As a part of our analyses of the latest and most significant mobile phone designs, we’ve conducted a thorough teardown of Apple’s iPhone 13, specifically, a US model that includes millimetre-wave 5G radios tuned for carriers in that market. The iPhone 13 offers several updates to a design that’s otherwise identical to the iPhone 12 — Apple’s first 5G smartphone released a year ago. In this article, we highlight the most significant changes to the core electronics and their impact on the bill of materials as a global chip shortage increased component costs over the past year.

The value of a teardown analysis is measured in the insights it uncovers. CCS Insight goes beyond identifying components and revealing how a product is made; the unique value of our teardown service lies in the cost benchmarking expertise and decades of experience we bring to bear.

There are very few differences between the outward appearance of the iPhone 12 and the iPhone 13. The latest device now has a smaller top screen notch, giving a slightly larger viewing area, and a new camera system with lenses placed diagonally as opposed to the linear pattern of the iPhone 12. However, inside the device, we can see many more significant changes that bring a whole year’s worth of development and updates.

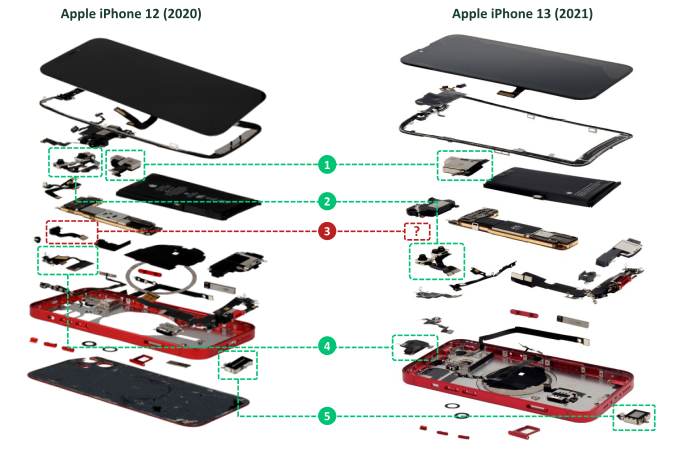

Some of the upgrades are evident. For example, Apple has improved the camera system in the iPhone 13 using the “sensor shift” image stabilization technology debuted on the iPhone 12 Pro Max in 2020 (see item one in the image below). This type of “trickle-down” technology is common as phone-makers like Apple exploit their enormous scale to drive down the cost of new technology.

The 3D-sensing Face ID module, largely unchanged since its introduction in the iPhone X in 2017, has been slimmed down to fit into a narrower screen notch, corresponding to item two in the image above. However, this update has eliminated space that Apple had previously used to fit a third (broadcast only) millimetre-wave antenna (item three). Eliminating an antenna, especially a sophisticated one, does raise eyebrows. But the one found in the iPhone 12 was regarded as an auxiliary 5G antenna and less important than the two main receive and broadcast millimetre-wave antennas. Improvements in 5G radio design from the iPhone 12 to the latest model likely rendered the third antenna unnecessary, and the physical changes to the Face ID module clearly forced Apple to drop this antenna.

Other updates we discovered include a more unified and compact ultra-wideband antenna (item four) and a different haptic motor design (item five), which we believe is used by the iPhone 13 and 13 Mini models in an effort to simplify and streamline component count and supply chain complexities.

A particularly interesting finding has to do with Apple’s custom system-on-chip A15 Bionic processor. Compared with the A14 Bionic processor in the iPhone 12, the A15 at the silicon level is 22% larger in absolute silicon real estate. Both chips are fabricated on TSMC’s 5 nm process, so the more than 4 billion additional transistors added to the size of the A15 processor. This difference is noticeable even at the packaged level: the A15 package is taller (17.2 mm compared with 14.8 mm for the A14) relative to a common fixed width (13 mm) defined by the main printed circuit board (see image below).

Apple made significant enhancements to its new A series processor, but without an improvement in silicon process the A15 processor had to grow in size as well as complexity. This immutable fact highlights the critical importance of semiconductor fabrication economics, in which silicon advances increase in parallel with improving process nodes. In the absence of a process update, the cost of the A15 chip invariably rises.

Diving deeper, when we compared the historical costs of Apple’s A series processors and correlated transistor counts, we discovered an interesting trend in the latest generation of Apple system-on-chips. Just as Moore’s Law describes, the number of transistors doubled at a pace of roughly every two years. Therefore, if we plot the logarithm of the transistor count in Apple A series chips, a linear trend appears as the transistor density keeps growing with each generation (see chart below).

Along the same time frame, from 2016 to 2021, we can also plot the cost per transistor, as we’re able to determine the cost of Apple’s silicon. To our surprise, the decline in cost per transistor stalls between the A14 and A15 processors. This cost-per-transistor metric tells us that the wonderful economics of Moore’s Law are beginning to break apart even as the rate of miniaturization continues at the transistor level. This is a worrisome trend that points to the rising cost of the main chipset used in iPhones.

If Apple moves its next A16 Bionic processor to a more advanced process node, which may very well be the N4 or N3 process by TSMC, the reduction in transistor size and the economics that these process nodes provide should put the cost-per-transistor back on track. This look at a major cost driver for the iPhone highlights the unrelenting pace of innovation Apple is subjected to as it strives for the bleeding edge of both mobile and silicon technology.

With more than a decade of lessons from Apple iPhone design, a fuller picture emerges as insights about cost-per-transistor trends, for example, illuminate and inform how this iconic product has evolved and will continue to do so. Apple has pioneered many technologies that the rest of the mobile phone industry has largely adopted, including the first unibody mid-frame construction, which doubles as the physical antenna introduced in the iPhone 4.

Clearly, Apple has been an industry-leader and innovator in smartphone design, but even the most innovative companies produce flops. For the iPhone, one such example was 3D Force Touch. The inclusion of this pressure-sensitive touch overlay increased the cost of the entire display module and when it became clear that consumers weren’t using it, Apple relented and abandoned the feature.

Click here to download a free copy of our report giving insights on our teardown of the iPhone 12.

Stories like this and many others are uncovered by our teardown and cost-benchmarking service informing technological evolutions and market dynamics. Here at CCS Insight, we look forward to upcoming device innovations and teardowns to bring you a unique view into not just how designs are achieved but also why.

Twitter

Twitter

Facebook

Facebook

LinkedIn

LinkedIn

Email

Email